The furniture covering trend

Give Your Furniture a New Lease of Life Transform tired furniture with furniture vinyl wrapping — a creative and affordable way to refresh your home or business interiors. This modern technique uses decorative adhesive films designed to cover and restyle existing furniture. Instead of replacing, you can easily update your look and save both time and money. Whether you want to revive an old bookcase, coffee table, or kitchen cabinet, vinyl wrapping adds new colour, texture, and design. It’s a practical, sustainable solution that delivers a stunning finish without the hassle of traditional renovation. A Versatile Technique for Every Interior Furniture wrapping works on most smooth surfaces, giving strong adhesion and professional results. You can apply vinyl films to cabinets, wardrobes, drawers, and even door frames for a coordinated design. In addition, it’s ideal for highlighting small interior details that make your space stand out. A Cost-Effective Way to Renovate Covering your furniture with decorative adhesive film is an affordable alternative to buying new. Many decorators and homeowners choose this fast, efficient method to refresh interiors on a budget. Moreover, vinyl furniture wrapping is quick to install, allowing you to transform an entire room in just a few hours. A Cost-Effective Way to Renovate Covering your furniture with decorative adhesive film is an affordable alternative to buying new. Many decorators and homeowners choose this fast, efficient method to refresh interiors on a budget. Moreover, vinyl furniture wrapping is quick to install, allowing you to transform an entire room in just a few hours. An Eco-Friendly Renovation Option Furniture vinyl wrapping is a sustainable choice for interior renovation. Rather than throwing away perfectly functional furniture, you can reuse and restyle it with modern finishes. This approach reduces waste, supports upcycling, and helps lower your carbon footprint — a small change that makes a big difference for the planet. Unleash Your Creativity Vinyl wrapping gives you the freedom to design unique, personalised furniture that reflects your individual style. With hundreds of textures, colours, and finishes available — from wood grain and marble to matte black and high gloss — you can easily create a look that’s truly your own. At The Wrap Centre in Paisley, we specialise in furniture and interior vinyl wrapping, serving homes and businesses across Glasgow and throughout Scotland. Enquiries, contact our sales team on 0141 611 3185 or e-mail admin@wrap-centre.com

Are Vinyl Wrapped Kitchen Doors Any Good?

Are Vinyl Wrapped Kitchen Doors Any Good? Vinyl wrapped kitchen doors are covered kitchen cabinet doors with a thin, self-adhesive vinyl film to change their look. In actual practice, it involves using sheets of some decorative vinyl by sticking them on the surfaces of your current kitchen cupboard doors/drawers. The vinyl adheres to the shape of the door, generally with heat, to stretch along the edges, thus creating this new finish. These wraps have limitless styles (solid colours, wood grains, marble patterns, etc.), so you can attempt the appearance of costlier materials. The idea is simple: rather than painting or even replacing your doors in your kitchen, you “wrap” them in a new style. Pros of Vinyl Wrapped Kitchen Doors Now, let’s explore the pros and cons of vinyl kitchen wraps, but first, the pros: Budget-Friendly Upgrade: Vinyl wrapping is significantly cheaper than buying all new cabinet doors or a complete kitchen refit. A brand-new kitchen can easily cost well into five figures, whereas wrapping your existing doors often costs only a few hundred to a couple of thousand (depending on your kitchen size). It’s a smart way to refresh your space without overspending. Quick and Low-Mess Installation: Unlike a traditional remodel, wrapping involves no heavy construction. There’s no need to rip out units or remove all the doors, so there’s virtually no dust, noise, or debris. A professional can wrap a kitchen in as little as a day or two for a fast transformation. You can often continue using your kitchen during the process, since there’s minimal disruption. Huge Range of Styles: Adhesive vinyl films come in hundreds of colours and textures, from realistic woodgrains and stone patterns to high-gloss solid colours and even metallic or textured effects. This means you can achieve almost any design vision. A vinyl wrap will likely suit whether you want modern matte black cabinets or a light oak timber look. You are not limited by what a manufacturer offers in door styles, you can mix and match looks easily. DIY-Friendly and Convenient: Applying vinyl wrap does not usually necessitate any special know-how or equipment that specialists must use. The procedure is to clean the surface, remove the film’s backing, and apply it to the door. Many homeowners can do it alone as long as patience and, perhaps, even a heat gun for corners are involved. Easy to Maintain: Vinyl-wrapped doors are easy to clean and maintain after installation. The vinyl makes a wipeable, waterproof surface that is great for kitchens. You can remove spills and grease with a damp cloth and mild detergent. Humidity in a kitchen will not affect good-quality vinyl films. Cons of Vinyl Wrapped Kitchen Doors Limited Lifespan: A common question is, How long do vinyl kitchen wraps last?A high-quality wrap typically lasts five to ten years before you may want to replace it. This is an excellent lifespan for a cosmetic upgrade, even though it doesn’t match the decades-long durability of solid wood cabinetry or a factory paint finish. Over time, the adhesive may weaken, or the vinyl can show wear, so consider wrapping as a medium-term solution. Possible Peeling or Bubbling: Another common issue involves vinyl peeling at the edges or forming bubbles. This problem often occurs when the film wasn’t installed correctly or when it’s exposed to excessive heat and steam.For example, cabinet doors above kettles or beside ovens often experience lifted edges sooner because of high temperatures. Although premium films resist heat, prolonged exposure or direct sunlight can still degrade the adhesive over time Repairs Require Rewrapping: Vinyl wraps can’t be touched up like paint. When a section becomes scratched or starts to peel, the best fix is to remove and replace that specific piece. For instance, if one door develops bubbles or lifting edges, that door’s vinyl wrap should be reapplied for a seamless finish. Who Is Vinyl Wrapping Right For? Vinyl wrapped kitchen doors can be an excellent solution for a wide range of people, but they’re especially well-suited to specific situations: Budget-Conscious Homeowners: If you want to refresh your kitchen’s look without spending a fortune, vinyl wrap is ideal. It delivers aesthetic impact for a relatively small cost, so you can stretch your renovation budget by covering existing units instead of buying new ones. Renters and Tenants: Vinyl wraps are one of the most popular renter-friendly kitchen upgrades for good reason, as they’re non-permanent. You can personalise a bland rental kitchen with adhesive vinyl and remove it without damage, avoiding deposit disputes. It’s a clever way to get a stylish kitchen in a rental home where painting or replacing doors is prohibited. Interior Designers & Home Stagers: Vinyl wrap offers tremendous flexibility for design professionals or home stagers. It allows you to experiment with bold colours or trendy finishes on cabinetry without permanent alteration. Designers can cost-effectively achieve high-end looks (marble, walnut, industrial concrete, etc.) to suit a client’s vision. And if tastes change, it’s easy to update again. Final Thoughts Vinyl wrapped kitchen doors can be a game-changer for your kitchen, offering a fast, affordable, and stylish makeover with minimal hassle. They’re not a one-size-fits-all solution, but for many homeowners and renters, they strike the perfect balance between cost and benefit, giving you a “new” kitchen look without the usual headaches. Ready to explore this option further? Check out our blog for more kitchen door makeover ideas, browse the benefits of adhesive vinyl wrap, and view our case studies to see real-life vinyl wrap transformations. With some creativity (and the right vinyl film), you might be just a weekend away from the kitchen of your dreams! enquiries, contact our sales team on 0141 611 3185 or e-mail admin@wrap-centre.com

Why Vinyl Wraps Are Ideal for Wardrobe Renovations

Why Vinyl Wraps Are Ideal for Wardrobe Renovation Vinyl wardrobe wrapping is a smart, affordable way to transform tired sliding doors or built-in wardrobes. It costs less than replacing or repainting and gives you more freedom to choose colours, textures, and finishes. They’re Affordable Compared with full replacements or custom painting, vinyl wrapping is the clear, cost-effective option for wardrobe renovation. It saves money on materials, labour, and disruption while still delivering a flawless finish. They’re Tenant-Friendly CoverStyl’s furniture films rest smoothly on surfaces and can be removed without leaving damage. This means tenants can refresh their spaces without upsetting landlords or risking deposits. They’re Customisable With vinyl wraps, you can choose any finish — matte, gloss, textured, or patterned. You’re never stuck with one expensive option, and you can update your style whenever you like. They’re Instant You can go to bed with an outdated wardrobe and wake up to a sleek, modern design. Vinyl wrapping gives you an instant transformation without the noise, dust, or mess of renovation work. Why Not Just Replace or Paint? Most wardrobes still have solid frames even when the doors look worn. Buying new ones adds unnecessary cost for materials and installation, not to mention extra noise and mess during fitting. Painting may look like a cheaper solution, but it brings its own issues. Most wardrobe doors are laminate or high gloss, and paint struggles to stick. You need sanding, priming, and several coats — and even then, the surface can chip or fade. Vinyl wrapping avoids these problems. It requires no sanding or priming, adheres perfectly to smooth surfaces, and lasts for years with daily use. You’ll enjoy more design options, better durability, and a cleaner finish. If you want to refresh your bedroom without spending heavily, wrapping offers the perfect balance of cost, speed, and quality. Styles and Finishes That Work for Every Room Wood-Grain Vinyl Choose warm, natural tones that add texture and character. Wood finishes pair beautifully with soft lighting and earthy colours for a timeless look. Matte Finishes Matte black, grey, or neutral tones create a clean, modern style. These are ideal for minimalist interiors or contemporary apartments. Marble and Stone Textures Add a polished, luxurious touch. Marble and stone effects work well with metallic accents or neutral walls to create a calm, elegant feel. Glossy Whites and Creams Make smaller rooms look brighter and more open. Glossy vinyl wraps reflect light and are perfect for compact bedrooms or flats. How to Protect Decorative Vinyl Wraps Clean with a soft cloth and mild soap. Avoid harsh chemicals or abrasive pads. For glossy finishes, use microfibre cloths to prevent streaks. If an edge begins to lift, gently re-seal it using a hair dryer or heat gun. You don’t need new doors to create a fresh look. Upgrading wardrobes with vinyl wraps gives you control over your design and budget. It’s the easiest way to modernise a room without the cost, mess, or downtime of traditional renovation. If you’re looking for wardrobe vinyl wrapping in Paisley or Glasgow, The Wrap Centre offers a wide range of CoverStyl vinyl options designed for beautiful, long-lasting results. Enquiries, contact our sales team on 0141 611 3185 or e-mail admin@wrap-centre.com

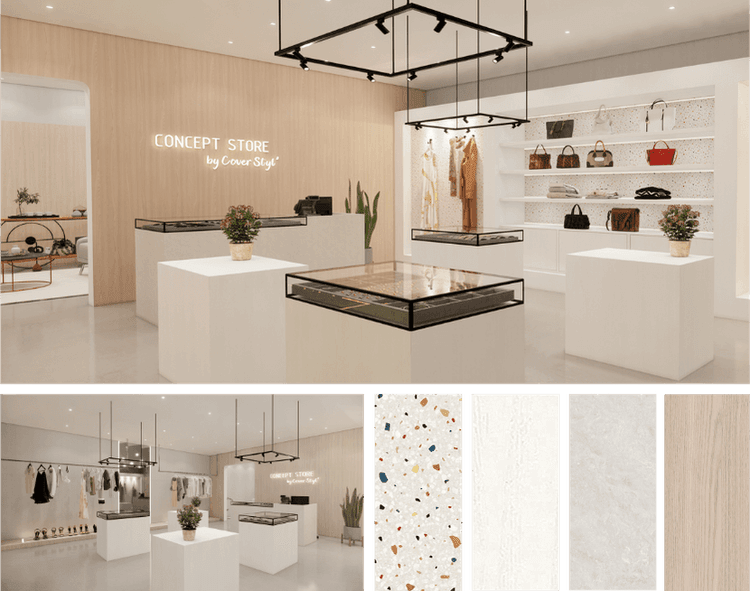

Architectural Film Wrap in Retail: Boosting Sales Through Visual Impact

How Film Wrap Boosts Retail Sales Through Visual Impact People shop with their eyes first. Surfaces play a bigger role in buying decisions than many realise. A smooth matte, brushed metal, or warm oak texture can completely change perception. Architectural films give retailers the power to apply these finishes instantly to retail projects — without demolition or costly fit-outs. A single wrap can transform a tired entrance, unify disconnected spaces, or strengthen branding with intentional design. Consistency matters. Even subtle upgrades catch attention. That quick glance, that moment when someone stops and keeps browsing — that’s where sales begin. For ideas on which finishes work best in retail environments, visit our blog on choosing the right commercial wrapping vinyl finishes. Where Retail Benefits Most from Film Wrap Applications Architectural film doesn’t just add style — it solves real problems quickly. Here are the key retail areas where vinyl wrap makes the biggest difference. Storefronts and Entrances First impressions start here. A metallic gradient, branded pattern, or deep matte finish sets the tone instantly. It signals quality and draws customers inside before a single word is spoken. Display Zones and Shelving Products stand out when the backdrop adds contrast. Woodgrain or concrete-textured vinyl adds depth, directing attention to featured merchandise. Explore our concrete finish collection for retail surfaces that bring texture and dimension without the weight or cost of real stone. Cash Desks and Counters These are high-touch, high-traffic areas. A vinyl wrap refreshes worn counters while adding subtle texture — soft-touch, stone-like, or lightly reflective. It conceals wear and reinforces your brand aesthetic. Dressing Rooms and Feature Walls Fitting rooms should feel current, clean, and well-designed. With vinyl film, you can refresh walls seasonally or between campaigns. One month it’s terrazzo, the next it’s soft walnut or pastel tile. No paint, no sanding — just peel, apply, and go. Comparing Film Wrap to Paint, Laminate, or Full Refits Traditional renovations are slow, messy, and expensive. Paint chips. Laminate peels. Complete refits close your store and increase labour costs. Decorative architectural film installs directly onto smooth, clean surfaces — usually in hours, not days. There’s no demolition and minimal disruption. The finish looks built-in yet remains flexible for future updates. When franchises rebrand or retailers update seasonal themes, film comes off cleanly and a new wrap goes on. It’s one of the few solutions that supports both consistency and flexibility — all while controlling costs. Proven Results: Film That Looks Great and Performs Real-world results show how effective film can be. One retailer wrapped shelving walls in a walnut finish and saw category sales increase. Another applied brushed gold film to an elevator lobby, and customers began photographing it. That kind of engagement doesn’t happen with plain drywall. Cover Styl’ architectural films are made for commercial use — scratch-resistant, easy to clean, and durable under heavy traffic. It’s not just decoration; it’s a design solution that enhances branding, performance, and customer experience. For more retail surface ideas, explore our commercial vinyl wrapping solutions designed for long-lasting results in high-traffic environments. Final Thoughts Retail moves fast. Trends shift, and stores can’t afford downtime. commercial vinyl wrapping gives brands a way to adapt quickly — staying current with trends, campaigns, and customer expectations without costly rebuilds. Cover Styl’ films are built for retail environments. They deliver creative freedom, visual consistency, and long-term durability. With vinyl wrap, your store can look better, sell better, and adapt faster — all without closing the doors. For more inspiration, visit our blog on choosing the right finish for retail projects and discover how film wrap turns everyday interiors into inviting, high-performing retail spaces. Contact our sales team on 0141 611 3185 or e-mail admin@wrap-centre.com

How Porsche Garage Reduced Temperatures in Their Showroom by Eight Degrees with Sun Protection Window Films from 3M

How Porsche Garage Reduced Temperatures in Their Showroom by Eight Degrees with Sun Protection Window Films from 3M With the help of Spandex Germany and 3M, the Porsche garage has taken a smart step towards sustainability and energy efficiency. By installing solar control window films in their Baden-Baden showroom, they successfully reduced temperatures by 8 degrees. Creating a more comfortable environment for their customers and employees alike. As an established innovator in the automotive industry, it’s no surprise that Porsche wanted an innovative solution for their showroom. With raising energy costs and global temperatures, it’s getting increasingly harder for everyone to keep comfortable temperatures inside their space. Not to mention the environmental impact of using multiple air conditioning units. With the space being a showroom, there are many windows letting in plenty of natural light to showcase all the cars on display. Naturally, all of this resulted in higher temperatures during the summer months, more sun glare and more UV rays coming in. The traditional solutions would be to turn up the air conditioning or install blinds. But luckily, Porche found a much better and cost effective option: Sun Control Window Films. By simply installing 3M’s films on all their windows, they managed to reduce indoor temperatures by 8 degrees and shift from using 3 air conditioners to only 1. As well as reducing glare on screens and preventing UV radiation from damaging the interiors. All of this was done while the showroom was open for visitors and working as normal. The project also aligns with Porsche’s commitment to be carbon neutral by 2030. While this is only a small step, it contributes to the company-wide initiative. The solar control window films were supplied by Spandex and installed by Konzept Marketing Services, a 3M certified partner in the architectural space. Their long experience in the field, and the support of 3M, helped them complete the project with minimal disruption to the business, while also ensuring the correct glass film was chosen for the purpose and environment. We’re very excited to have been a part of this exciting project. Watch how the whole project came to life: https://youtu.be/LqFyBW1LssA

The Evolution of Vehicle Wrapping

The Evolution of Vehicle Wrapping Vehicle wrapping has undergone a remarkable evolution, from simple colour changes to breathtaking visual transformations, advancements in technology, materials, and design techniques have elevated vehicle wrapping into an art form. THE BIRTH OF VEHICLE WRAPPING Vehicle wrapping originated as a cost-effective alternative to custom paint jobs. In its early days, the focus was primarily on basic colour changes. Vinyl films emerged as a breakthrough material, offering a more flexible and reversible option for vehicle customisation. Vehicle owners could now change the appearance of their vehicles without committing to a permanent alteration. ADVANCEMENTS IN VINYL FILMS Technological advancements in vinyl film manufacturing have significantly improved the quality and durability of materials used in vehicle wrapping. High-quality adhesive materials ensure long-lasting adhesion, even in challenging environmental conditions. Superior colour pigmentation results in vibrant and fade-resistant wraps that maintain their visual impact over time. Advanced protective coatings provide increased resistance to UV rays, scratches, and chemical damage, enhancing the longevity of the wrapped vehicles. EXPANDED COLOUR OPTIONS In the early stages of vehicle wrapping, colour choices were limited. However, with advancements in printing technology and the manufacturing of vinyl films, the colour palette has expanded dramatically. Vehicle owners now have access to a wide range of vibrant and metallic finishes, enabling them to choose bold and eye-catching colours for their wraps. Additionally, colour-shifting films have gained popularity, allowing vehicles to display a stunning array of hues depending on the viewing angle or lighting conditions. Textures and Specialty Finishes The introduction of textured films has opened up new possibilities for vehicle wrapping. These films replicate the appearance of materials such as carbon fibre, brushed metal, or matte finishes. The inclusion of speciality finishes adds depth, uniqueness, and a touch of luxury to wrapped vehicles. Textured wraps have become increasingly popular among car enthusiasts and individuals looking to create a distinctive and customised look for their vehicles. Custom Designs and Graphics The integration of digital printing technology has revolutionised vehicle wrapping, enabling the reproduction of intricate designs, logos, and artwork for vinyl films. This has given vehicle owners the freedom to express their individuality through personalised designs and branded graphics. Custom wraps allow businesses to transform their vehicles into mobile advertisements, effectively promoting their brand and capturing attention on the road. Full Wraps and Partial Wraps As vehicle wrapping techniques advanced, full wraps gained popularity over partial wraps. Full wraps provide comprehensive coverage, transforming the entire vehicle’s appearance. They offer a seamless and cohesive look, ensuring that no part of the original vehicle colour is visible. Full wraps have become the go to choice for those seeking a complete vehicle transformation, whether for personal or commercial purposes. Vehicle wrapping has undergone a remarkable evolution, from simple colour changes to breathtaking visual transformations, advancements in technology, materials, and design techniques have elevated vehicle wrapping into an art form. The Birth of Vehicle Wrapping Vehicle wrapping originated as a cost-effective alternative to custom paint jobs. In its early days, the focus was primarily on basic colour changes. Vinyl films emerged as a breakthrough material, offering a more flexible and reversible option for vehicle customisation. Vehicle owners could now change the appearance of their vehicles without committing to a permanent alteration. Advancements in Vinyl Films Technological advancements in vinyl film manufacturing have significantly improved the quality and durability of materials used in vehicle wrapping. High-quality adhesive materials ensure long-lasting adhesion, even in challenging environmental conditions. Superior colour pigmentation results in vibrant and fade-resistant wraps that maintain their visual impact over time. Advanced protective coatings provide increased resistance to UV rays, scratches, and chemical damage, enhancing the longevity of the wrapped vehicles. Expanded Colour Options In the early stages of vehicle wrapping, colour choices were limited. However, with advancements in printing technology and the manufacturing of vinyl films, the colour palette has expanded dramatically. Vehicle owners now have access to a wide range of vibrant and metallic finishes, enabling them to choose bold and eye-catching colours for their wraps. Additionally, colour-shifting films have gained popularity, allowing vehicles to display a stunning array of hues depending on the viewing angle or lighting conditions. Paint Protection and Surface Enhancement Vehicle wrapping has expanded beyond aesthetics to encompass practical benefits. Paint Protection Films (PPF) have become an integral part of the wrapping process. PPF shields the vehicle’s original paintwork from scratches, rock chips, and UV damage while enhancing its visual appeal. This dual function has made paint protection an attractive option for vehicle owners looking to preserve the value and condition of their vehicles. Cutting-Edge Installation Techniques Advancements in installation techniques have played a crucial role in achieving seamless and professional-looking wraps. Precision cutting tools, such as plotter cutters, ensure precise and accurate trimming of vinyl films. Heat guns are used to soften the film, allowing it to conform to complex curves and contours of the vehicle. Post-heating techniques help eliminate any remaining tension, resulting in a smooth and uniform finish. Innovation in Wrapping Tools and Equipment The vehicle wrapping industry has witnessed continuous innovation in tools and equipment. Heat-assisted laminators have made the process more efficient by providing uniform heat distribution, enabling optimal adhesion, and preventing bubbles or wrinkles. Advanced vinyl cutters equipped with optical alignment systems ensure precise and error-free cutting. Application aids, such as magnets and squeegees, assist installers in achieving flawless results. The Rise of Unique Wrapping Styles The evolution of vehicle wrapping has spurred the emergence of unique and creative wrapping styles. Colour flips, chameleon effects, textured wraps, and even three-dimensional designs are pushing the boundaries of imagination. Colour flips allow vehicles to display different colours depending on the viewing angle, creating a mesmerising visual experience. Chameleon effects provide a range of colour variations as light reflects off the vehicle’s surface. Textured wraps simulate the look and feel of materials, adding a tactile dimension to the wrap. Three-dimensional designs create optical illusions, making vehicles stand out and captivate attention. The evolution of vehicle wrapping from basic colour changes to striking

The Future of Vehicle Wrapping

The future of vehicle wrapping The world of vehicle wrapping is constantly evolving, driven by advancements in technology, materials, and consumer demands. As we look to the future, exciting trends and technological innovations are shaping the landscape of vehicle wrapping. Today, we’ll explore the emerging trends and advancements that are set to transform the industry and revolutionise the way we customise and protect our vehicles. Advanced Materials and Finishes Innovations in materials are paving the way for new possibilities in vehicle wrapping. Manufacturers are developing vinyl films with enhanced durability, improved conformability, and superior colour retention. These materials offer better resistance to UV rays, chemicals, and environmental elements, ensuring that wrapped vehicles maintain their pristine appearance for longer periods. Additionally, advancements in finishes, such as metallics, iridescent, and textured films, provide even more opportunities for creating unique and eye-catching designs. Sustainable and Eco-Friendly Solutions As environmental consciousness continues to grow, the vehicle wrapping industry is embracing sustainability. Manufacturers are introducing eco-friendly vinyl films that are free from harmful substances and have reduced environmental impact during production and disposal. Water-based inks and solvent-free adhesives are also becoming more prevalent, minimising the release of volatile organic compounds (VOCs). These sustainable solutions not only benefit the environment but also appeal to eco-conscious consumers and businesses. Digital Printing and Customisation Digital printing technology has revolutionised the world of vehicle wrapping, allowing for intricate and high-resolution designs. With advancements in large-format printers, vehicle wrap installers can achieve stunning graphics, gradients, and photorealistic images with ease. The rise of customisation is also driving the demand for personalised vehicle wraps. Digital printing enables the creation of one-of-a-kind designs tailored to individual preferences, making each vehicle truly unique. Augmented Reality and Interactive Wraps The integration of augmented reality (AR) with vehicle wraps opens up new avenues for interactive experiences. AR wraps can incorporate scannable codes or markers that trigger digital content when viewed through a smartphone or tablet. This technology enables businesses to engage their audience with interactive promotions, games, or immersive brand experiences. Imagine a wrapped car that comes to life with animated characters or a food truck that offers a virtual menu through AR. The possibilities for engagement and marketing are virtually limitless. Electric and Autonomous Vehicles The rise of electric and autonomous vehicles presents unique opportunities for vehicle wrapping. As these technologies become more prevalent, designers and manufacturers are considering the specific needs and characteristics of these vehicles when developing wrap solutions. The ability to integrate branding, safety features, and communication elements on the exterior of electric and autonomous vehicles opens up exciting possibilities for advertising, information dissemination, and visual identity. The future of vehicle wrapping is bright, driven by technological advancements and evolving consumer demands. Advanced materials and finishes ensure long-lasting durability and stunning aesthetics. Sustainable solutions appeal to eco-conscious consumers and businesses. Digital printing and customisation enable intricate designs and personalised wraps. Augmented reality and interactive wraps engage audiences in innovative ways. And as electric and autonomous vehicles become more common, wrapping solutions tailored to their unique characteristics will arise. The future of vehicle wrapping holds endless possibilities, allowing us to transform our vehicles into personalised, protected, and interactive canvases on the road ahead. Are you passionate about the world of vehicle wrapping? Download our Vehicle Wrap Brochure to explore our full range of products.

3M Expands 2080 Wrap Film Series with Eight Stunning New Colours

3M has unveiled eight bold new additions to its popular 2080 Wrap Film Series 3M has unveiled eight bold new additions to its popular 2080 Wrap Film Series, giving installers even more choice when it comes to vehicle customisation. Available from today, these new colours feature a mix of high gloss and satin finishes, expanding the range’s versatility and visual impact. The New Colours Satin Sandstone (2080-S49) Satin Lunar Blue (2080-S87) Satin Komodo Green (2080-S56) Satin Frozen Berry Metallic (2080-S238) High Gloss Nardo Gray (2080-HG61) High Gloss Meteor Gray (2080-HG81) High Gloss Mantis Green (2080-HG36) High Gloss Ruby Rosso (2080-HG73) Check out the new colours below!